We have encountered this great article on What Is Sewer Pipe Lining? below on the net and think it made sense to relate it with you on my blog.

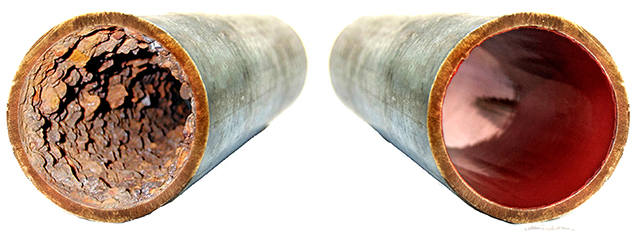

Pipeline relining is a relatively brand-new principle as well as a long-overdue choice to the typical technique of dealing with drainage issues by excavating. It avoids the excavation procedure leaving structures intact as well as returning your drainage to its previous glory. Obstructed drains pipes, split pipelines, origin instruction, built up sedimentation, and lots of various other problems connected with drain systems can currently be fixed utilizing this approach. It simply includes finishing the old pipelines with a substance that is delegated embed in the shape of the old pipeline. The old pipeline currently functions as a defense for the freshly formed ones, therefore getting rid of drainage problems in the local future. Improvement water drainage problems while bordering structures remain intact is an excellent benefit of this procedure. While pipe relining seems like an appealing option for property owners it is a solution that calls for unique ability as well as training that a routine plumber might not be able to deliver. For this reason you ought to seek advice from accredited and also trained plumbers that are knowledgeable in pipe relining.

We evaluate and also determine the pipelines

First, we send the drain video camera to examine the plumbing system to locate any breaks and pipe obstructions, and also measure up. This aids us exercise specifically what the trouble is and also where it's positioned.

Benefits of Pipe Relining

Negative Aspects of Pipe Relining

Pipe relining is a procedure that needs specialized skill. Hence, it can not be done by just any plumber. Likewise, valuable as it may be, it is not appropriate for all cases. As an example, in cases where the pipeline has large fractures or large inner voids, the remaining remedy will certainly not have the ability to create a certain shape. Pipeline patching can be performed in instance of smaller damage.

The relined area is checked and also examined

Once your pipeline has actually been relined, we use our CCTV drainpipe inspection electronic camera to inspect that every little thing has actually been set up and sealed appropriately.

The Relining Process

As has currently been mentioned, the relining procedure must be accomplished by experienced as well as qualified professionals if the procedure will certainly be successful. It takes specific succinct as well as deliberate steps to get the job done effectively.

Drain Examination

This is the initial step focused on both checking the degree of damages and the feasibility of the pipe continuing to be as the remedy to the issue at hand. It is finished with a drainpipe camera. The cam is positioned within the pipe and the footage is used to detect any abnormalities such as pipe imbalance, missing out on sections, little or huge gaps, as well as aged pipeline material.

Drain pipes Clearing up

After it has been verified that pipeline relining is possible, the drain should be cleared of any type of obstruction with particles, sediments, as well as obstructions. This is generally done with a high-pressure jet of water. The drainage is after that observed with the cam once more to determine any clog that may affect the relining procedure.

Relining Appropriate

A custom-made lining bladder is made and also put into your drain to coat the inner surface with lining resin. Compressed air is used to spread the material equally on the internal surface area of the pipelines. Ultimately, the layer is entrusted to heal and set for the following few hours.

Final Inspection

It is necessary to inspect the outcome of the continuing to be process to figure out if it succeeded or not. This is performed with the exact same drain camera method as was made use of for the first assessment. Hereafter, your newly relined drain is ready for use.

How Does Pipe Relining Work?

How This Process Works

Pipe relining works by fixing your pipes from the inside. A flexible felt tube made of polyester or fiberglass and saturated with resin is inserted into the existing, damaged pipe. Over time, this special resin hardens to form another pipe within the original pipe. This method is considered trench-less technology because it involves minimal digging and forms a much simpler and more cost-effective alternative for traditional pipe repair methods.

Steps for Pipe Relining

Step One: Verify the pipe is a suitable candidate for relining: First, a professional installer examines your pipes to assess the extent of the damage. This used to be accomplished with closed-circuit cameras, but today forced electron leak location (FELL) equipment provides a more thorough inspection and allows for the creation of more effective solutions.

Step Two: Prepare and measure the pipe: Next, the blocked pipes are thoroughly cleaned to return them to their original dimensions. Regular cleaning methods are employed first and any blockages are removed, usually with robotic cutters. After this, a high-pressure water jet ensures the pipe walls are fully clean and ready for the resin to attach. The camera equipment is employed a second time to verify the pipe is ready for insertion. Then, the length of the pipe is calculated to determine the length of the lining.

Step Three: Insert and cure pipe liner: The flexible felt tube saturated with epoxy resin is inserted into the pipe. Inside the tube is a bladder that inflates and pushes the tube to form to the inner walls of the pipe. Next is curing, the longest part of the process. Hot water is used to harden the resin, followed by UV radiation to cause final hardening. Before the process can be complete, junctions and inspection pits must be cut out. Junctions are removed with robotic cutters, while inspection pits are removed with grinders or surface-level cutters.

Step Four: Final inspection: The bladder is deflated and removed, then the installer uses the remote camera again to verify that the liner has been placed appropriately.

I was guided to that article about What Is Pipe Relining from an associate on a different web property. If you please take the time to distribute this write-up if you liked it. Thanks so much for your time invested reading it.

24/7 ready, dial!